The rapid digital transformation across the globe has led to phenomenal demand for advanced electronic components. Semiconductors are the basis for all modern technology. Semiconductors are embedded in our smartphones, laptops, automobiles, and defense technologies. Semiconductors are critical to anything that we think of as being modern. With India’s expanding technology ecosystem, we are now progressing into the semiconductor ecosystem.

Understanding the Semiconductor Industry

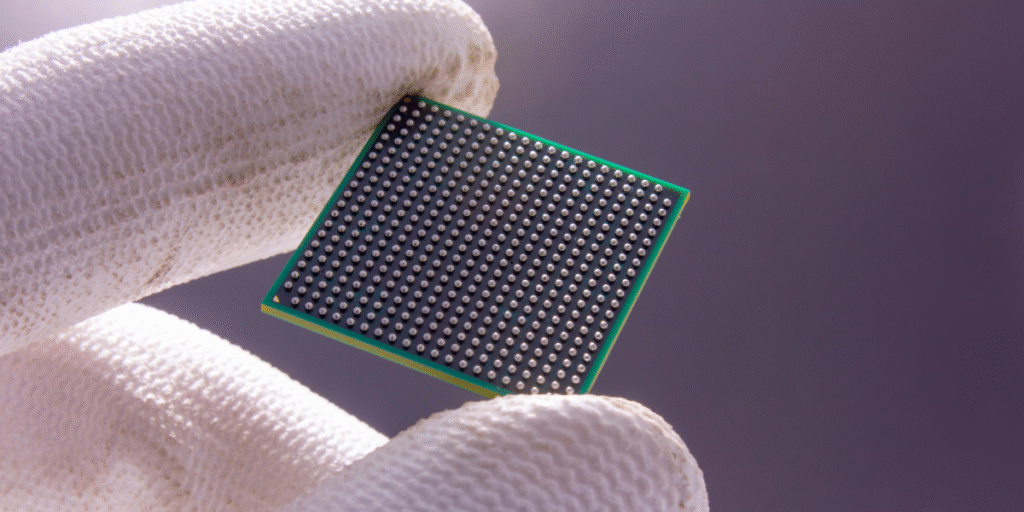

A semiconductor is a material that has electrical conductivity between that of a conductor and an insulator. The unique and intermediate nature of the semiconductor makes it important in the fabrication of electronic circuits and chips. The dominant semiconductor manufacturers in the world, such as Taiwan, South Korea, and even the USA and Japan, have been emerging nations. Today, India is trying to make its mark, attracting investments, creating manufacturing, and encouraging research in semiconductors.

The Rise of Semiconductor Companies in India

In the last decade, India has experienced impressive growth in the design segment and testing segment within semiconductors. Although large-scale manufacturing is still developing, semiconductor companies in India are emerging fast through their research and design innovation and working with global majors. The Government of India also pushed the semiconductor sectors expansion through initiatives such as “Make in India” and the Production Linked Incentive (PLI) scheme.

Key Semiconductor Companies in India

1. Tata Elxsi

Tata Elxsi is a top player in semiconductor design and embedded systems. The company is recognized with its expertise in chip design, product engineering, and system integration into consumer electronics, automotive, and healthcare product areas.

2. Broadcom India

Broadcom, one of the leading semiconductor companies in the world has its R&D centers in India. The company focuses on networking devices, broadband access, and wireless communication. The company’s Indian operations are crucial for the company’s semiconductor development across the globe.

3. Intel India

Intel is also one of the biggest investors in semiconductor R&D in the country. Intel India has multiple sites in Bengaluru and Hyderabad where it focuses on projects related to microprocessors, cloud, and system-on-chip (SoC) designs.

4. Qualcomm India

Qualcomm is well-known for its contributions to wireless communications. Its operations in India are involved in the research and development of semiconductors that drive 4G, 5G, and IoT devices.

5. Micron Technology

Micron just made big news by establishing a semiconductor assembly and testing facility in Gujarat. This contribution is a milestone in India’s ambition to create a strong semiconductor ecosystem.

6. Samsung Semiconductor India R&D (SSIR)

Applied Materials is a worldwide leader in semiconductor fabrication equipment. The Indian R&D centers contribute directly to the productization of technologies to support the fabrication and packaging of chips.

7. Applied Materials India

Applied Materials is a global leader in semiconductor fabrication equipment and it has two R&D centers in India that support critical technologies for chip fabrication and packaging.

8. Wipro

While Wipro is not a semiconductor manufacturer, it plays a vital role in providing semiconductor design and testing services. It collaborates closely with global semiconductor companies to provide end-to-end chip design solutions.

9. HCL Technologies

HCL Technologies has also been in the semiconductor space by providing engineering services and verification and validation support to chipmakers throughout the world.

10. Sankalp Semiconductor

Sankalp Semiconductor is an Indian enterprise that focuses on analog and mixed-signal design; specifically, they have a presence in the automotive, medical and industrial applications space.

Government Initiatives to Boost Semiconductor Companies in India

- The Indian government is keen on achieving semiconductor self-reliance.

- A few key initiatives are as follows: Semicon India Programme: Initiatives to lure international semiconductor manufacturers and to support aspiring Indian startups including a $10 billion programme.

- PLI Scheme: Monetary incentives up to 25% for semiconductor manufacturing, design and assembly units.

- Electronics Manufacturing Clusters (EMCs): Emergence of special zones to provide the necessary infrastructure support to semiconductor and electronics companies.

- Work collaboratively with other semiconductor related entities: The government is working with the US, Japan, Taiwan eras along with promoting SMEs to enhance it capabilities.

Challenges Faced by Semiconductor Companies in India

- Despite the large potential, semiconductor companies in India have several disadvantages:

- High Capital Expectations: Fabs require billions of dollars to set up.

- Skills Gap: Although India has many engineers, expertise in the complex area of semiconductors is limited.

- Supply Chain Dependency: India is heavily reliant on imports for raw materials and fabrication equipment.

- Competition from Unique Countries: Competing with companies in places like Taiwan (TSMC) and South Korea (Samsung) is difficult without domestic manufacturing.

Future Prospects of Semiconductor Companies in India

The future appears bright against the backdrop of challenges. The digital economy in India, the boom in the smartphone market, and the initiative to develop electric vehicles, will all lead to greater demand for semiconductors. With helpful policies from the government and investments from the private sector, India is on a path to creating a semiconductor ecosystem. By the year 2030, India anticipates being one of the largest semiconductor markets in the world.

Why is India Emerging as a Global Semiconductor Destination?

- India is becoming an appealing option for semiconductor companies for many reasons:

- Large Domestic Market: Over 1.4 billion people means demand for electronic devices is significant.

- R&D Talent: India churns out qualified engineers with a background in chip making and testing at a steady rate.

- Government Incentives: Programs and subsidies are incentivizing global players to establish their portfolios in India.

- Geographic location: India’s position in the world is another plus for global supply chain diversification.

The part that Startups play in the Semiconductor Ecosystem

India’s semiconductor ecosystem also features startups. Companies such as Saankhya Labs, Invecas, Tessolve etc., offer design services, chipsets, testing services, helping to connect the global giants and our local innovative capabilities.

Conclusion

While semiconductor companies in India have only begun their journey, they have made excellent progress so far. Along with robust support from the Government, combined with global partnerships and local players coming into being, India is well poised to become one of the top semiconductor hubs in a few years.

FAQs Semiconductor Companies in India

Q-1. Who are the key semiconductor companies in India?

A- Companies at the top of the semiconductor industry in India include Intel India; Tata Elxsi; Qualcomm India; Micron Technology; and Broadcom India.

Q-2. Does India make semiconductors?

A- India is heavily focused on semiconductor design and R&D, however, the recent Micron investment with plans for a facility in Gujarat indicates that manufacturing and assembly are moving from the drawing board to reality.

Q-3. What does the Indian government do to support semiconductor companies?

A- Government-led initiatives, like the Semicon India Programme and the PLI scheme, are meant to attract investment and enable the cooperation of ecosystem players.

Q-4. Why do we need semiconductors for India?

A- Semiconductors, necessary components in smartphones, laptops, vehicles, defense systems and IoT solutions, are key to growth of Indian digital ambition.

Q-5. What is the future for semiconductor companies in India?

India’s semiconductor companies are well positioned with demand growing, government support, and global partnerships, to become a global hub for manufacturing and assembly by 2030.